Why Hardox® Wearparts?

Preformance – Hardox® wear plate is the world’s leading abrasion-resistant (AR) steel. Hardox® is both hard and tough, from the surface deep down to its core. It can take hard blows and resists crack propigation giving you extended service life and high productivity in the most challenging environments. Hardox 500 Tuf will last 4.4x longer than mild steel and 1.5x longer than typical OEM wear parts

Uptime – Extended wear life produces less downtime, allowing the user to run longer and harder than with typical OEM wear parts. This will translate to longer service life and less maintenance for your operation

Cost Savings – For approximately the same cost as generic AR plate, your wear parts lifetime will increase 1.5x on average. You may be able to use thinner material, saving you money and fuel or increasing payload and productivity. Less downtime for maintenance or repair will yield better production quotas. Hardox® wear parts are a great investment that will immateriality affect your bottom line.

Reducing your Carbon Footprint – Whether you agree or disagree with the carbon economy; Hardox® wear parts will reduce your carbon footprint. SSAB is leading the way in recycling and fossil free steel by lowing carbon emissions from the mill. You will need less of it thanks to it’s extraordinary service life. Your equipment can be lighter increasing savings on fuel or energy needed for production. You can reduce your carbon footprint with a simple change to a superior product.

Information about wear

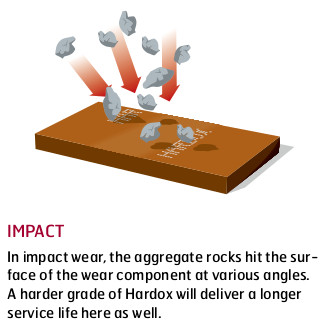

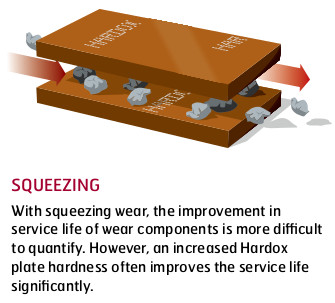

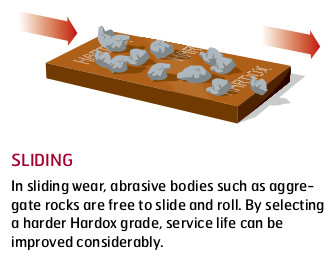

Wear comes in different forms and each has a different impact on the service life of your application.

The most common wear types are sliding wear and impact wear. Abrasive particles trapped in a narrow gap between two rigid surfaces causing squeezing wear is also a common wear type.

Each variety of rock is composed of a unique set of minerals and these also contribute to the specific type of abrasive wear damage.

WearCalc software, available from our Technical Managers, describes and calculates the relative differences between materials. It allows you to predict relative wear life and com pare different wear solutions.

Whatever your application and wear situation, Hardox is your ticket to outstanding wear performance.

Hardox Overview (SSAB site) Strenx Overview (SSAB site) Duroxite Overview (SSAB site)

What parts are better with Hardox®?

With Hardox®, Strenx® and Duroxite® from SSAB; anything is possible

- Blades

- Blow bars

- Bucket side cutters

- Cavity walls

- Centrifugal fan blades

- Chain conveyor floor plate

- Cheek plates

- Conveyor floor plate

- Conveyor guides

- Cutter wheels

- Cutting edges

- Delimbing knives

- Discharge chutes

- Dragline rigging

- Drill tubes

- Excavator pins

- Fan blades

- Fan housing

- Flighting

- Floor plate for road pavers

- Forklift forks

- Grizzly bars

- Grizzly bar seats

- Hammer mill hammers

- Harrow discs

- Harrow tines

- Harvester blades

- Header augers

- Heel shrouds

- Hooks

- Impact plate

- Intermediate Y chutes

- Knives

- Liner plate

- Lip shrouds

- Log conveyor chains

- Log cradles

- Outlet chutes

- Paddles for conveyors

- Pulverizer jaws

- Pulverizer teeth

- Rakes

- Rigging

- Ripper points

- Ripper shanks

- Road paver runners

- Rotor caps

- Rotor discs

- Scrapers

- Screed plate

- Screens

- Screw feeder flighting

- Shafts

- Shanks

- Shear blades

- Shear blades for shredders

- Shells

- Shredder rakes

- Shroud for log conveyors

- Shrouds

- Sieves

- Sprocket wheels

- Stump grinder discs

- Tamper shoes

- Trawl door shoes

- Troughs for conveyors

- Wear bars

- Wear pads

- Wood chipper drum